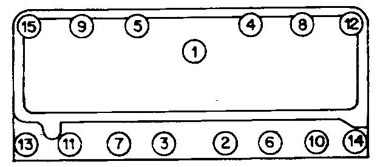

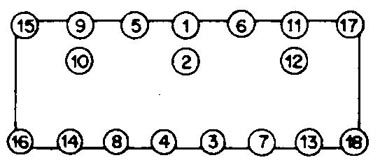

When removing and replacing the cylinder heads in any internal combustion engine, the tightness and tightening sequence of the head bolts is critical to a good seal. Fel-Pro gaskets has a great little booklet that provides that information for just about any engine ever made. Below, find the information for the three kinds of in-line six engines found in Advance Design pickups.

Use a sealer. Copper Coat is good, as is Aviation Permatex. Silicon (RTV) is NOT. Neither is oil, water or grease. Guide the head down with installation studs or cut off head bolts. Failure to do this will probably cause a head gasket shift, not good on a 1/8" overbore. Use a light oil on the threads. If the bolts go into the water jacket as on the late model Chevy 194 - 292 You should use a sealer. Aviation Permatex, or my favorite, Loctite’s Teflon thread lock and sealer. Again, NO SILICONE (RTV).

Torque down the head with at least three sequences. For example; 30 ft.lbs., then 60 ft. lbs., and finally 90 ft. lbs. Bring the head up to operating temperature without driving it. Then shut it off. Re-torque the head while the engine is still warm. The best way to do that is to loosen each bolt ½ a turn. Do one bolt at a time, then bring that bolt up to the final, full torque in one smooth, even pull. That should do it, drive it and have fun. By the way while you are warming it up, if it has a new cam do not let it idle under 1500 RPM for the first hour. And make sure you have plenty of coolant, this is no time to overheat.