Under the hood of your 1947-1953 Advance Design Chevy Truck can be a pretty dark place depending on ambient lighting. By using two BA15 (1156 single element) sockets pointed at each side of the engine, that is no longer a problem. The reason this solution is only for 1947-1953 is because the 1954/55 trucks do not have holes placed properly for our new addition. I do not have a 54 or 55 truck to play with.

This solution mounts under the front hood support using two completely un-used holes placed 5 inches apart. We thank Chevy for putting those holes there for us! I am referring to the two holes on each side of the hood latch spring.

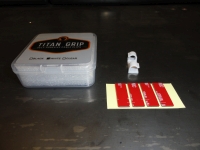

By using the TitanGrip wire holders that stick on using the 3M adhesive method, we can route the wires from the lights to a suitable power source. The most elegant power source is also right there under the hood in your Horn Relay! The center terminal of the Horn Relay is +12 volts and the top terminal is ground. Confirm this before connection with a multimeter. You should get +12 volts at the center terminal of the Horn Relay.

Install using the included two 1/4" bolts. The assembly is designed using real stainless steel nuts embedded in the plastic. Do not overtighten. Just tighten until the lock washer squashes down. Before installation, if you want the lights to be pointed more left or more right, it is possible to slightly bend the metal bracket to accommodate your wishes. The up and down angle is pretty fixed. Don't forget to push the switch back in when you are done using it!

The assembly has a push/pull switch located in the center for easy on and off operation. The LED's are very low power and very bright. If you want to make this yourself using your own 3D printer, contact Deve and I will get the .STL file to you. The parts list is as follows:

I am sure this is more costly than you would like. I agree! The problem is 3D printing technology is still in its infancy and it takes two full days non-stop to print this assembly. Then, the wiring is done with cloth covering and that takes time. A full metal solution would be better in some ways, but not-so-much in another...the plastic is better on painted surfaces. Two simple brackets that would not be hard to fabricate would save you a lot of money! The color of the 3D printed assembly is Black! I used Yellow on this prototype because my truck is yellow.