Between 1947 and 1953 the only choice Chevy offered for their Advance Design Series Trucks was a Splash Oiler in two different sizes, the 216 and the 235. These were Babbitt motors meaning the bearings were poured rather than the newer style Insert Bearings. This is notable because these trucks experienced very heavy use and these motors weren't really up to the task of Post World War Two commerce. Chevy corrected this problem in 1954 with the first pressurized motor with Insert Bearings. The 235 and 261 was born. These engines stood up very nicely to all challenges and really helped boost Chevy's reputation at the time.

These days we see a lot of '47-'53 Chevy trucks with the newer style 235 engine because most of them were replaced pretty early on in their lifetime. These are not delicate engines, they are real workhorses, and competed and even outclassed Fords F-1 offerings with the flathead V8. Chevy enthusiasts these days who want to keep a nice 6 cylinder between the frame rails have two good choices for replacing their tired worn out old engine, the 235 or the 261 built between 1954 and 1962*.

Between 1954 and 1962, Chevrolet produced their famous full oil pressure 235 cubic inch six-cylinder in trucks and it soon proved to be one of the greats among engines. However, at the same time a lesser known "big brother" to this base engine was being used. This was the venerable 261 cubic inch six cylinder! This 261 was available only in 2-ton (6000 or C60 series) trucks and school buses. During it's early years (1954-57) it was an extra cost option above the standard 235 six-cylinder.

In 1958-62 (the 261 now had a full flow remote oil filter) it became standard in the 2-ton chassis up to 19,000 pounds gross weight. Above that Chevrolet substituted a V-8. This larger six was not offered in US cars, however there was an exception in Canadian built full-size Pontiac's. Their base engine, also produced only in Canada, was the 261 not the V-8 as in the US. This provided basic power, great dependability, and better gas mileage.

Basically, this larger engine was a 235 with the same crankshaft but GM engineers made various modifications to give it extra strength and horsepower. Its standard bore diameter increased from 3-9/16 inches to 3-3/4 inches. The connecting rods were heavier and attached to increased diameter piston wrist pins.

Its higher lift camshaft, for better breathing, was shared only with the early 235 six cylinder Corvette. A modified larger Rochester carburetor was also a 261 only feature. Unfortunately, most of these larger sixes have long since had their original Rochester's replaced with 235's and therefore do not perform to their full potential. (See Carb Section Below)

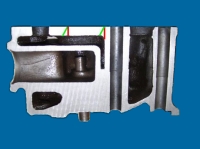

In pure big truck form the 261 has a larger thermostat housing holding a double acting thermostat. This is designed to circulate water through the block and head before the thermostat opens to allow hot water into the radiator. Thus, no internal steam hot spots during warm ups, especially in winter. This is particularly important with very cold coolant. Vital engine spots can become very hot before the total coolant becomes hot enough to open a normal thermostat on the front of the block.

Below is the statistical data to illustrate the difference between the 235 and 261.

|

|

|

|

| Displacement | 261 Cu. In. | 235.5 Cu. In. |

| Bore | 3-3/4" | 3-9/16" |

| Stroke | 3-15/16" | 3-15/16" |

| Firing Order | 1-5-3-6-2-4 | 1-5-3-6-2-4 |

| Compression Ratio | 7.8 to 1 | 8 to 1 |

| Horsepower | 33.7 (AMA) 148 (Rated) | 30.4 (AMA) 140 (Rated) |

| No. of Main Bearings | 4 | 4 |

| Wrist Pin Diameter | 0.927 inches | 0.866 inches |

|

Rod Shaft Thickness Front to Back |

0.595 inches | 0.595 inches |

|

Rod Shaft Thickness Side to Side |

0.975 inches | 0.760 inches |

|

Crankshaft Journal Diameter |

2.435 | 2.435 |

| Engine Color in trucks |

Green - some later yellow |

Gray |

It may also be of interest to know the displacement numbers for the different over-bore sizes. This information is easily ascertained by

working through a basic formula using the numbers in the chart above. The formula is:

|

|

|

|

| .000 Stock | 260.930 Cu. In. | 235.490 Cu. In. |

| .010 Over | 262.323 Cu. In. | 236.813 Cu. In. |

| .020 Over | 263.721 Cu. In. | 238.141 Cu. In. |

| .030 Over | 265.121 Cu. In. | 239.472 Cu. In. |

| .040 Over | 266.526 Cu. In. | 240.807 Cu. In. |

| .050 Over | 267.934 Cu. In. | 242.146 Cu. In. |

| .060 Over | 269.346 Cu. In. | 243.488 Cu. In. |

| .070 Over | 270.762 Cu. In. | 244.834 Cu. In. |

| .080 Over | 272.182 Cu. In. | 246.184 Cu. In. |

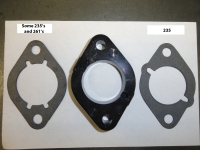

Although quite rare, the 261 had it's own Rochester B Carburetor with increased capacity. The reason they are rare is they look to most people exactly the same as the 235 Carb and they usually ended up in the rebuild stream with the 235 Carbs of the day. To see which one is the correct one, there are four indicators that will provide you with the clues you need. The picture on the left is the Throttle Body differences between the 235 and 261. Not only is the 261 larger, but note the placement of the vacuum hole. The picture on the right verifies the vacuum holes are different. Both gaskets are available depending on which Carb Kit you get. The 261's Throttle Body (bottom) measures 1.750 inches while the 235 measures 1.500 inches across.

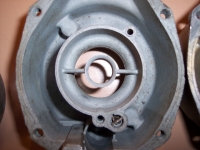

These pictures are offered to show the differences in the bottom of the Carbs Fuel Bowl with the throttle body removed. If you

look closely, you can see a significant difference in size and style. The 235's fuel bowl measures 1.575 inches across while the

261's measures 1.750. It is also noteworthy that the main Jet sizes are larger on the 261. While most 235's are around .056 depending

on the year, the 261's can be as large as .068. The internal passage between the Jet and the Power Valve is larger as

well at .0635.

Shown here is the fuel bowl comparison. This is the easiest way to tell if you have a 261 Carb without taking it off. If you can

see down the carb, you can get a pretty good idea of which one you have. As you can see, the Venturi is significantly wider on the

261. If you do not have a 261 Carb, not to worry. The 235 Carb has been successfully installed on the 261 engine for years and most

vehicle owners do not even know. You might lose a little top end, but other than that, that combination has been around for many

years without notice.

After four years into production, a major quality feature was added to the 261 engine. For the first time a Chevrolet in-line six-cylinder came standard with a full flow oil filter system. This improvement, used only with the later 261, forced oil through a remote filter cartridge before it reached the engine. It was not like the optional by-pass oil filter system as found on 216 and 235 Chevrolet sixes. This new system helped insure longer life to this larger six-cylinder, which was often subjected to heavy commercial use. This means that if you have the older 1954-1958 261 Engine if it has an Oil Filter at all, it will be a Bypass Filter System. (more information below).

A full flow oil system has been a characteristic of almost all automotive engines for over 40 years but it was just beginning in the mid 1950's. With the 261, the disposable filter is remote and not built in as with later engines. It still resulted in a major design improvement.

As with the 235 light truck engine, the 261 came standard with solid valve lifters and an aluminum camshaft timing gear. The passenger car's 235 was equipped with hydraulic valve lifters and a fiber timing gear for quieter operation.

During the 1955-62 Canadian Pontiac application the lifters were the hydraulic type, the cam gear was fiber not aluminum, and it did not have the full flow oil filter. These Canadian made 261's did not add the full flow filter in 1958 as in the U.S.

Visually the 261 looks almost identical to the 235. It perfectly replaces the smaller engine and in stock condition increases horsepower from 140 to 148.

Those planning on a major rebuild or adding performance options to their Chevrolet in-line six should seriously consider locating a 261. Often there is no extra cost in purchasing a rebuild-able unit, and the results will be rewarding. If you plan on adding additional carburetion, a higher lift cam, or just want additional performance and more lower end strength in your daily driver, the 261 is for you!

Locating and Identifying a 261Though last placed in larger Chevrolet trucks almost 40 years ago, this now scarce engine can still be located and often at a price no higher than for the smaller 235. Many still remain in the original Chevrolet trucks and are now setting in salvage yards or behind farm buildings. In Canada, the big Pontiac cars are sometimes in the back rows of more isolated older wrecking yards.

Don't overlook the wrecked and badly rusted Chevrolet cars of the 1940's and 1950's, particularly those showing signs of some past exterior customizing changes. The Chevrolet enthusiasts of that era knew about the 261 and its potential for added performance. Some of these will already have had extras added such as a higher lift cam shaft, extra carburetion, or dual exhausts.

When you have found what you suspect might be a 261, check a few specifics to verify you have the real thing and not the visual

almost identical 235. Casting numbers, not stamped numbers, on the 261 head are very visible beside the rocker arm cover.

A different set of numbers relate to the 261 block. These seven digits are located on the right side between the fuel

pump and starter except for 1954 where it is located forward of the fuel pump. See chart below.

|

YEAR |

ENG. SIZE |

BLOCK NO. |

HEAD NO. |

||||

|

54-55 |

261 |

3703414 |

3733950 |

3702436 |

3703570 |

3836850 |

3835499 |

|

55-57 |

261 |

3836340 |

3837012 |

3738813 |

3703570 |

3836850 |

|

|

58-62 |

261 |

3739365 |

3769717 |

3769925 |

3836850 |

|

|

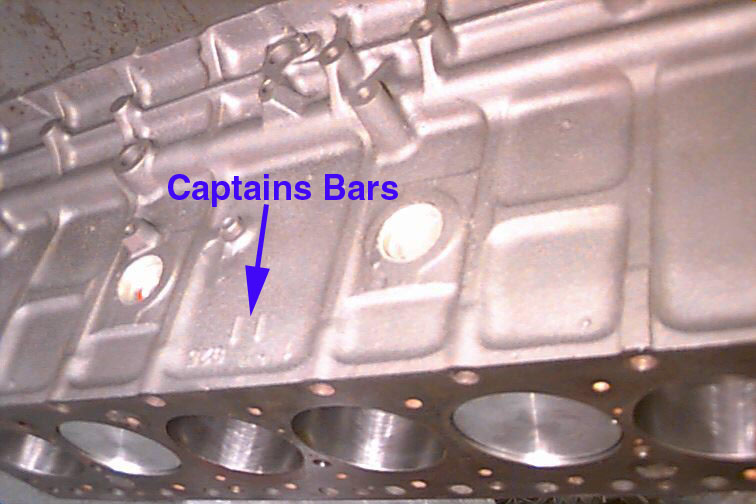

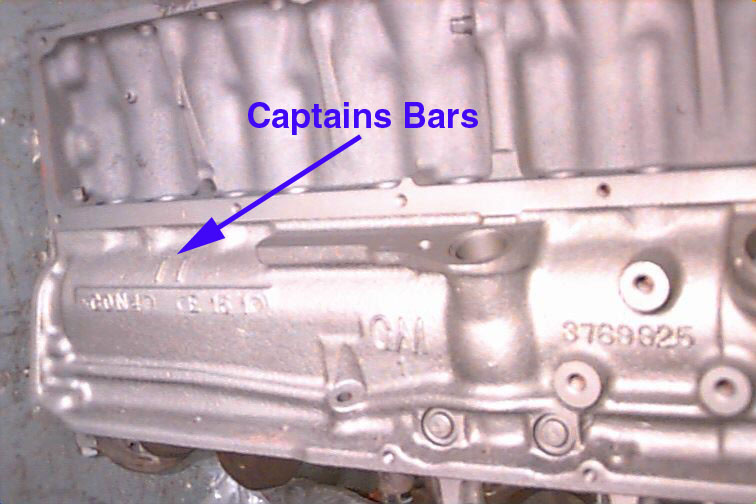

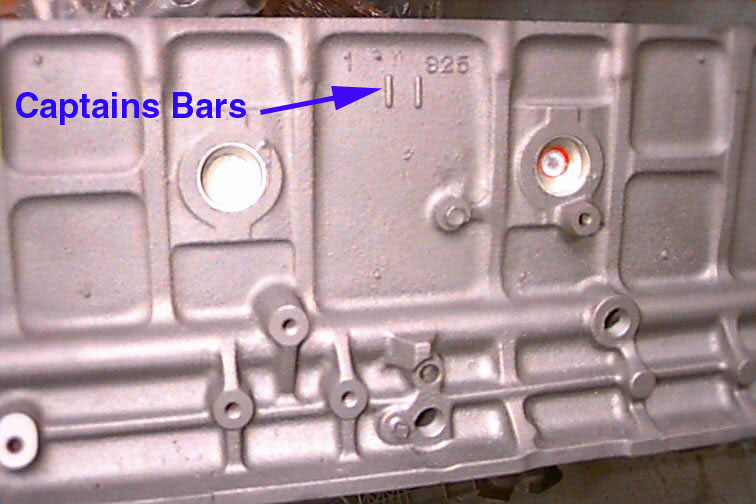

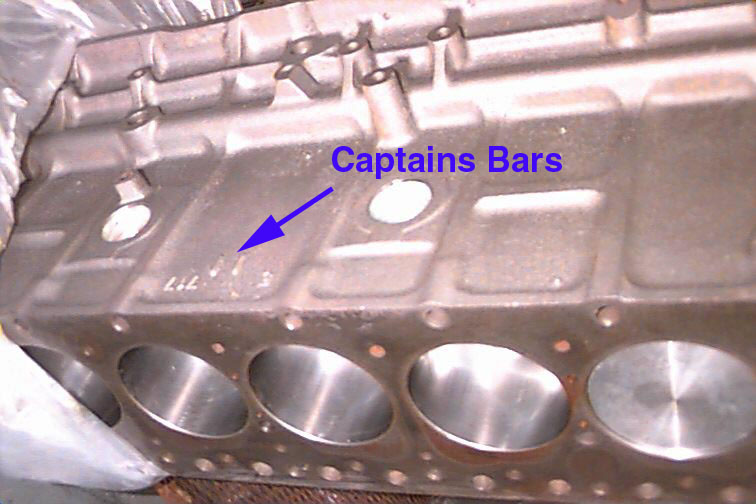

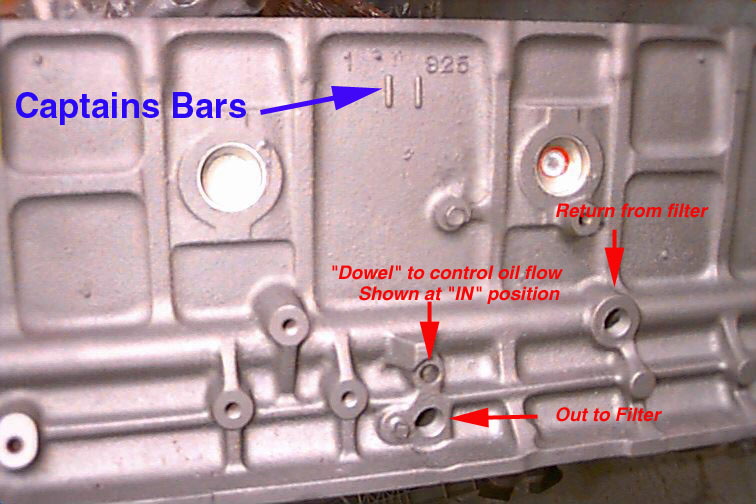

Watch for the "Captain Bars! The 261 has two pairs of parallel raised 3/4 inch long bars cast in the block. This is not seen on a 235 except in 1953 (w/ Powerglide Transmission) where there is only one set of Captain Bars on the passenger side just above the starter. On the 261, One pair is above the starter and the second pair is at the top middle of the left side of the block very close to the head. See photos below. Also, note the odd marking on the final picture. This is also a 261 but very rare. Information about that one is very sketchy.

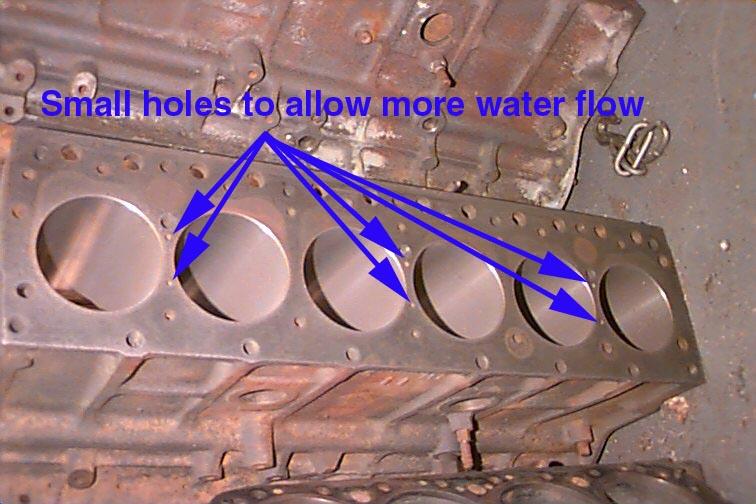

Most used 261 blocks are re-build-able, however often their cylinder heads will have a few very small cracks in the combustion chamber. This is typical due to occasional abuse of over heating in past years. If you choose not to add to your expense by having the cracks repaired, an alternative exists. The more common 235 head is the same except for the three pair of internal steam holes. These can be manually drilled to make the water flow just like in the 261! Sorry, but some 235 heads can be cracked even more than the 261 because they lack heat releasing steam holes.

The block and head surface have three pair of matching small water holes that allow any water/steam hot pockets to vent away from the open water cooled areas between the cylinders that are not solid metal. Of course, this means the 261 must have its own specialized head gasket.

A trick that people often use to increase the compression of their 261 is to use the higher compression '848 Head from a 235

engine. This head was the most produced and a great fit for your 261, however, you MUST drill the aforementioned water holes

in this head. To locate the holes, place the 261's Head Gasket on the Head and then mark the holes. Verify these 6 markings are

in the right place by measuring on the engine blocks surface just to be sure. Tape off or mask anything that could get metal

shavings in it and cause failure. Using a 3/16" Drill Bit, drill the holes into the Head's water cavity at 12 degrees as

shown. If drilling straight in would reliably intersect the water jacket GM would have done it that way. Take a look at why even a

slight angle towards the manifold side will improve chances of flow. Note that 3 of the holes are pretty much can’t miss and

the other 3 may not exit the head bolt boss if drilled straight. I’m sure there are folks out there that only have flow in 3

of 6 places but possibly that is just enough to get by. GM locations are in green and red shows straight in.

The 261 head resulted in lower compression than found on 235's with the "848" head from 1956-1963. GM/Chevrolet did increase

the 261 compression a little between 1954 and 1963, but the 848 head 235's always had higher compression. The 848 Head will

result in considerably higher compression than even the stock 261 850 Head on your 261 Engine. Be absolutely sure you know what

you are doing if attempting this drilling procedure. Most engine shops, with this document can do it with precision.

The stock remote full flow filter system has two very visible 1/2" lines threaded into the block. One is from the pump to the filter and the other from the filter back to the block. Oil must leave and return to the engine by these lines (even if the filter is eliminated) or the engine will fail from lack of lubricant. Many 261 engines have been quickly seized after persons plugged the two oil line holes. They had many years experience on Chevrolet engines without the full flow oil system. Some thought it was an easy fix to just remove the 1/2" lines if one was leaking and cap the holes. This procedure was acceptable on the older 216 and 235 but never on the 1958-62 261 truck engine.

Note: If you have a 235 or earlier model 261 but still wish to have a full flow oil filtration system, there is a How-To for that. That one is called Adding Full Flow Oil Filtration to your 235/261. But wait! There's more!

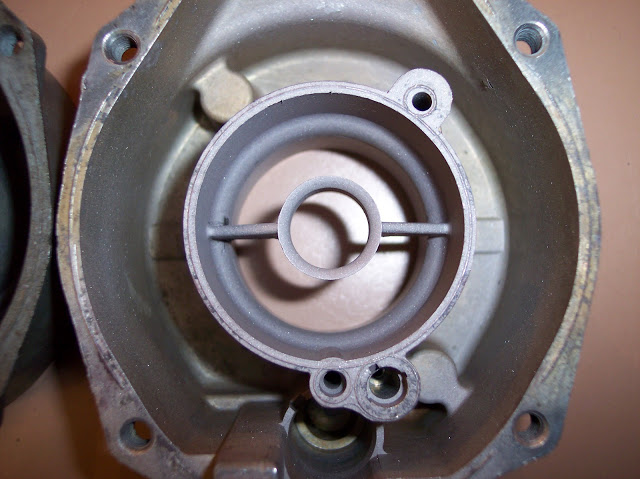

If you have a late 261 with the ½" pipe thread holes on the left side, great! These engines have a full pressure full flow oil filter system capability. What that means is that 100% of the oil from the pump goes through the filter before it enters the engine. Maybe! Over the lower hole, you will see a boss with a dowel in the middle. If the dowel is out flush with the block, there will be a passage opened between the oil pump outlet and the main oil galley. If the dowel has been pushed in, all the oil has to go through the filter first. The dowel passage is 1-5/8" long. The dowel itself is 1 inch long.

Shown on the right is the dowel in the BYPASS position. In BYPASS you must use a bypass oil filter system. This system usually

has smaller oil lines. To connect it, you connect one end to the small connection at the block (Out To Filter depicted above),

plug the larger 1/2" outlet beside it, then connect the other hose to the 1/2" (Return From Filter depicted above) using an

adapter. Bypass filters have their advantages. If the hoses connected to them break, your engine won't be completely starved of

its oil. This is a real concern when using a full flow system.

Note: You can use a full flow filter system on a bypass motor, but you have to narrow the passage at the engine block to keep your

engine from being starved. To do this, adapt the lower line down to fit the small port, plug the big lower hole, and add a Holley

carburetor main jet drilled out to 1/16" diameter to the fitting that screws into the 1/8" NPT port. A 1/4-28 tap is close enough

to the Holley jet thread to work. In other words, adapt the lower small port down to a 1/16" orifice.

Shown on the left is the dowel in the FULL FLOW position. In FULL FLOW you MUST use a Full Flow Filtration system OR you MUST connect the two large ports together. The proper depth for that dowel to be driven in to the block is 5/8" (or .63) below the surface of the boss. To use a Full Flow setup, cap off the small diameter hole next to the 1/2" diameter hole. It's a good idea to keep a proper length hose with the proper fittings to jumper the two large holes in case of a leak. The engine will not last very long if anything happens that those two holes are not ported together. The Chevrolet reference for the depth of this dowel is Chevrolet Parts and Accessories Manual 1929-1959.

For more interesting information on the 261 Engine and how to rebuild one, there is a nice write up about it at

Inliners.org

Many people helped to write this article. Some of it was compiled from other How-To documents. Special thanks to everyone who

contributed. This How-To effort is designed to bring to you the most complete and useful information possible in a simple, easy-to-read

format. Additions, Corrections, etc. contact deve@speedprint.com

If I forgot you, just drop me an email.. it was not intentional! Special thanks to the folks at 97330.com and their original writeup

The Forgotten 261. Thanks to Tim Lederman and his

Awesome Site! There is a lot there to digest. Thanks to Dave Folsom who helped make sure

we stayed on point with his research efforts. Check out Dave's Blog. Of course, we all

know that Jim Carter probably had something to do with this!

You found this at: DTN

We are developing more fun stuff for your engine. The Kits that are available now are Regular and Deluxe PCV Upgrade Kits, Spin-on Oil Filter Adapter Kits, and of course our popular HEI conversion kit. Check out all of our offerings at Farm-it-Out!